This story is part of Choosing Earth, a series that chronicles the impact of climate change and explores what’s being done about the problem.

Every year, smartphones get faster, more durable and capable of shooting sharper photos. But there’s another improvement that’s become more prominent in recent years: Our phones are increasingly made of more recycled materials.

Apple and Samsung, the world’s two biggest smartphone makers, are both ramping up the use of recycled materials in new smartphones and other products. Samsung aims to incorporate recycled resin into 100% of the plastics in its products by 2050. It’s already begun using materials from discarded fishing nets in its flagship and foldable smartphones. Nearly a fifth of all material used in Apple products in 2021 was recycled, and the company hopes to one day make iPhones completely from recycled materials.

Such ambitions are critical when it comes to reducing waste and the need to mine raw materials, which shrinks the carbon footprint of these devices. But these efforts aren’t entirely altruistic; they come at a time when consumers are increasingly factoring environmental impact into their purchasing decisions. The chip shortage also served as a reminder that obtaining fresh components and materials needed to build the devices that drive the tech industry’s profits might not always be an option.

Despite Apple and Samsung’s advancements, constructing a phone completely from recycled materials is still extremely difficult. Doing so would require a rethinking of the way mobile devices are built, from the supply chain to the materials needed for critical components and the way phones are sold. Apple and Samsung are making progress on these fronts, but scaling these efforts to an industrywide level is an astronomical, if not impossible, task.

“Apple says it’s doable, and I believe them,” said Michael Rohwer, director of the Americas for BSR, a nonprofit organization that provides sustainability consulting for businesses. “I don’t, however, think we’re very close.”

If a recycled phone happens, it will likely come from one or two companies

Apple’s recycling robot Daisy was designed to disassemble iPhones and recover valuable materials.

Apple

There are many reasons why you shouldn’t hold your breath for a smartphone completely made from recycled materials.

Companies need to develop systems for repurposing materials so that they’re durable enough to function properly in new devices. They also need to come up with new technologies for extracting materials from old devices — as Apple has done with its suite of iPhone-recycling robots like Daisy, Liam and Taz. At the same time, companies need to make sure new technologies and processes for turning waste into usable materials aren’t too carbon intensive, which would negate the benefits of recycling to begin with.

Samsung is familiar with such challenges. That’s part of the reason why Samsung intercepts discarded fishing nets before they end up in the ocean for use in products like the Galaxy S22, Galaxy Z Fold 4 and Galaxy Z Flip 4.

“If you wait until that stuff’s been sitting in the ocean and degraded to the point where it has to be completely reprocessed and unzipped chemically and then turned back into a nylon and then reformulated, well that that defeats the purpose,” said Mark Newton, head of corporate sustainability for Samsung Electronics America.

Smartphone specifications also vary greatly between companies, which makes materials hard to generally repurpose across the industry. There’s no guarantee that aluminum from an iPhone will meet the right needs for a Samsung phone, and vice versa, for example. That’s why we’re more likely to see a fully recycled phone from a single company, like Apple or Samsung, rather than a broad sweeping push across the industry, Rohwer said.

“There’s a really important distinction between an individual company being able to create a device completely from recycled materials … and the industry as a whole doing it,” said Rohwer.

Certain components in new Samsung products like the Galaxy Z Flip 4 and Galaxy Watch 5 are made from recycled plastics.

Samsung

For fully recycled phones to eventually become an industrywide practice, tech companies would need to collaborate on common standards for device specifications, according Rohwer. That, of course, would mean firms like Apple and Samsung potentially sacrificing some of their valuable intellectual property. The European Union is pushing for more ubiquity throughout the smartphone industry for that reason. In an effort to cut down on e-waste, the EU recently ruled that all phones and small electronics sold in Europe will need to use USB-C charging by 2024.

“It’s going to require them to see the business value of creating the recycled phone as being more valuable than the risk of losing some of that IP,” said Rohwer.

Last month, Apple confirmed an iPhone using that standard would be coming, although it didn’t offer a timeline.

While it may be unlikely that tech companies will collaborate on smartphone designs in the future, Apple and Samsung are making some of their sustainable tech publicly available. Apple has offered to license patents related to its recycling robot Daisy to other companies and researchers for free, while Samsung has open-sourced its SolarCell remote, which draws power from radio frequencies in addition to the sun.

What Apple and Samsung are doing today

Although creating a phone made completely from recycled materials may still be far off, Apple and Samsung have made some notable steps in recent years.

Apple’s and Samsung’s efforts are part of an industrywide push to make tech gadgets more sustainable. Microsoft’s mouse constructed from ocean-bound plastics (pictured) is another example.

screenshot/Microsoft

It’s part of a broader push within the tech industry to build products more sustainably. Microsoft, for example, developed a computer mouse made from ocean-bound plastics, while Dell introduced its Concept Luna laptop prototype, which is designed to consume less power and be more easily repaired. Google also touted how the Pixel 7 and 7 Pro’s aluminum enclosure is made from 100% recycled materials. But Apple and Samsung are in a strong position to make an impact within the mobile industry considering they make up roughly 37% to 38% of global smartphone shipments combined.

Apple said in 2017 that it wants to eventually only use renewable or recyclable materials in new products. In 2021, the tech giant included 45% certified recycled rare earth elements in its products, including 30% recycled tin and 13% recycled cobalt used in the iPhone’s batteries. It also introduced certified recycled gold into its products for the first time with the iPhone 13 and 13 Pro.

In addition to using materials from ocean-bound plastics in new products, Samsung also wants to make its devices more energy efficient by implementing new low-power technologies. By 2030, the company also aims to incorporate recycled resin into 50% of the plastic parts in its products and establish a system for reusing minerals from waste batteries.

The Galaxy phone maker is also exploring how it can repurpose other types of waste, although it couldn’t share details just yet. Samsung still needs to ensure that these raw repurposed materials can function properly under all circumstances.

“We have to be aware that not all waste can be incorporated in a smartphone,” said Pranveer Singh Rathore, a materials and research and development manager at Samsung. “[The] smartphone has its limitations. It is a high-performance device which has to perform the same way as it does in Siberia, as it does in Florida.”

The push for more recycled materials in new tech products means our old phones have become valuable resources for companies like Apple and Samsung. Apple opened up a materials recovery lab in Austin, Texas, in 2019 specifically to research new ways to recycle materials from used products.

That sentiment also drives how phone makers, wireless carriers and third-party retailers have pushed customers to recycle their old phones when purchasing new devices. Samsung, for example, offers up to hundreds of dollars off the Galaxy Z Fold 4 with a trade-in, while Verizon offers up to $1,000 off the iPhone 14 lineup when swapping out your old phone and activating with a carrier.

A facility for processing recycled electronics located in Fresno, California, managed by Samsung’s partner ERI.

Samsung

It’s difficult to discern how successful those efforts are globally. A report from the United Nations, and the International Solid Waste Association found that only 17.4% of global electronic waste was formally collected and recycled in 2019. In the Americas, that percentage shrinks to 9.4%, according to the same report.

But data from insurance and risk management services provider Assurant suggests that trade-ins are on the rise in the US. Customers in the US earned $767 million through mobile device trade in programs in the second quarter of 2022, representing an increase of 34% from the same quarter last year.

Aside from offering discounts as an incentive, businesses and governments are both boosting recycling efforts.Twenty-five states in the US have laws around recycling electronic waste, with the earliest being passed in California in 2003. Companies like Google and Samsung have also been rethinking the idea of how their mobile products are sold over the past couple of years.

Both companies have launched subscription services that enable members to swap out devices regularly and upgrade to the latest hardware. This type of model ensures phone makers are getting these devices back when they’re no longer in use, potentially providing more phones that can be refurbished or mined for materials.

And, of course, it also provides Samsung and Google with another revenue stream.

Phones need to last longer

James Martin/CNET

It’s not just about incorporating more recycled materials into new phones. Reducing the tech industry’s carbon footprint also means building phones that last longer, according to Autumn Stanish, a principal analyst for Gartner specializing in sustainability research.

That’s especially important now that inflation has weakened demand for new phones, with shipments expected to decline 6.5% globally in 2022, according to the International Data Corporation. Component shortages also caused shipments to fall in 2021, according to research firm Canalys, underscoring the need for long-lasting devices.

“What we’ve seen over the past couple of years has been a totally radical change in the mindset of the way that we think about devices and their lifespans, and how we use them and how we value them,” said Stanish.

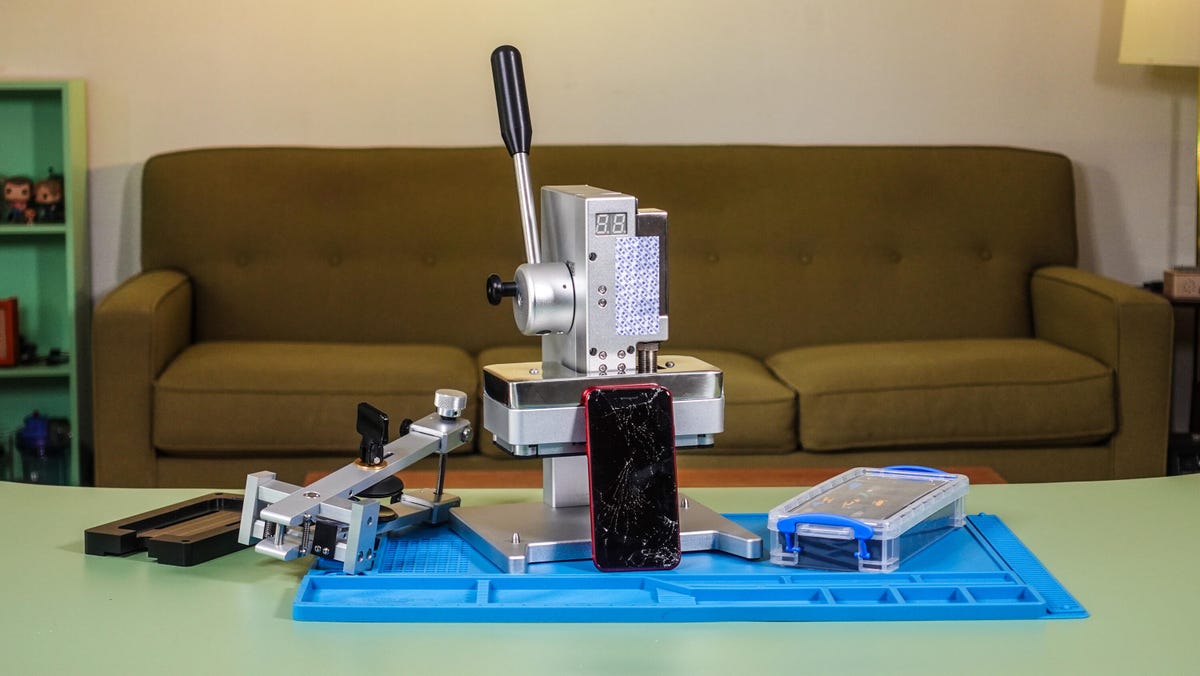

While companies like Apple and Samsung both offer several years of software support, they only just recently made it easier for consumers to repair their own smartphones. In April, Apple launched its Self Service Repair program, which allows customers to purchase Apple genuine parts and tools to perform repairs on their own iPhone 12, iPhone 13 and third-generation iPhone SE devices. Samsung also launched a similar program that allows device owners to self-repair certain Galaxy phones around the same time. Programs like these could be an even more effective way to make tech products more sustainable than incorporating more recycled parts.

A shattered iPhone SE pictured with tools from Apple’s self-service repair kit.

Chris Parker/CNET

But Apple and Samsung only launched these programs after self-repair advocates and legislators pushed for better access to DIY kits and maintenance services. Now the world’s largest phone makers must grapple with the conundrum of selling more devices while ensuring current models last for as long as possible.

That pressure is regularly reflected in quarterly earnings from both companies, particularly for Apple, which generates most of its revenue from iPhone sales. Apple’s iPhone revenue came up short of analysts’ expectations in its fiscal fourth-quarter earnings, per CNBC, while Samsung reported a 31% drop in profits for the quarter that ended in September because of weak demand for tech devices.

Another challenge, however, is getting the general public excited about sustainability as a selling point. Even though inflation is dampening consumer appetite for smartphones, data suggests that more people tend to splurge on brand new models rather than less expensive previous-generation iPhones. While demand for refurbished phones is growing, the iPhone 13 lineup accounted for the largest share of US iPhone sales in March 2022, according to Consumer Intelligence Research Partners. Apple also said in its earnings report that it hasn’t yet caught up with demand for the iPhone 14 Pro.

“We want new equipment, we want new devices,” said Stanish. “We want these kind of new form factors and things that excite us about technology, because that’s kind of the whole point of technology.”

She points to Fairphone, the Amsterdam-based tech company that promotes recycling and sells phones made from repurposed materials, as an example. Sustainability and responsible sourcing are the backbone of Fairphone’s branding and corporate identity, but Apple and Samsung dominate the global smartphone market by a wide margin. Apple accounts for 16% of worldwide smartphone shipments, while Samsung accounts for 21% as of the second quarter of 2022, according to Counterpoint Research. Xiaomi, Oppo and Vivo are the only other companies mentioned among the top five vendors, with Fairphone and others lumped into the vague “others” category.

It’s impossible to know when or if smartphones of the future will ever be made from 100% recycled materials. But at the very least, Apple and Samsung certainly have an opportunity to send a powerful message.

“The thing that would really make me excited is if it was open-sourced,” said Rohwer. “If these companies were willing to be transparent about how they got there, how that device got made, and use it as a roadmap for the rest of the industry.”

Correction, Nov. 7: The caption under the animated GIF incorrectly stated the source of some components of the Galaxy Watch 5. The source is recycled plastics.

Source by www.cnet.com