Even before it was signed into law in August, the CHIPS and Science Act had attracted the biggest manufacturers of semiconductors to commit to buidling fabrication plants in various parts of the United States, essentially “re-shoring” an industry the nation once dominated.

The measure is a $52.7 billion package of subsidies and grants to the US semiconductor manufacturing industry aimed at reducing US dependency on Asia-based silicon makers. The lack of US-based chipmakers recently led to a supply chain crisis for computer device makers, the automotive industry, and other industries dependent on the microprocessors to run their highly automated products.

Intel, Samsung, TSMC, and others have been executing plans for new domestic computer chip development and manufacturing plants, but those efforts are running into a new headwind: there aren’t enough high-tech workers.

A new study by Deloitte predicts that more than 1 million additional skilled workers will be needed by 2030 (100,000 annually) to support the global semiconductor industry. The industry saw $550 billion in revenues in 2021, and that number is expected to grow beyond $1 trillion by 2030. The problem? Fewer than 100,000 graduate students enroll in electrical engineering and computer science in the US each year.

Micron is the latest semiconductor maker to announce plans to build a memory chip fabrication plant in the US — in upstate New York. That facility is slated to be the size of 40 football fields and create about 50,000 jobs, and Micron may spend up to $100B on it over the next 20 years.

Dr. Martin Schmidt, president of Rensselaer Polytechnic Institute.

Martin Schmidt recently took over as president of Rensselaer Polytechnic Institute (RPI), a private research university in Troy, NY, that will be responsible for training a future semiconductor R&D and manufacturing workforce. Schmidt has a PhD in electrical engineering and computer science and spent 40 years at MIT, most recently serving as its provost. Prior to that position, he was MIT’s senior academic and budget officer, responsible for the Institute’s educational programs, as well as for the recruitment, promotion, and tenuring of faculty.

Schmidt spoke with Computerworld about the dearth of tech talent, what universities can do to fill it, and what impact the CHIPs and Science Act will have on reintroducing the semiconductor development and manufacturing industry within US borders.

The following are exerpts from that interview:

What happened to the US chip industry? “It’s important to note that if I reflect on my time in this field — I began as a graduate student in the semiconductor field in the early 1980s — this was an industry that was very strong in the United States and provided all kinds of career opportunities for people who chose to make that their field of work. Over time, however, you had the creation of the foundry business model and the increase in capital costs to build fabrication facilities. Those two things came together and really drove a reduction in the number of companies that felt they needed their own captive fabrication facility to take advantage of the microelectronics revolution that drove the foundry business model.

“Of course, much of what happened then were in parts of the world that were willing to subsidize the establishment of that fabrication facility…as part of an economic development agenda. That’s where many of the fabs went to.

“The dynamic it created for higher ed was that when you talk about someone who’s majoring in a particular discipline…, for those who are hoping to stay in the US for their entire career, it became less and less likely that was going to be a viable path. So, you saw a natural reduction in the number of people pursusing that.”

How has the CHIPs Act begun to address the severe lack of tech talent available to jump start these new investments in fabrication facilities? “What the CHIPs Act has done is created an opportunity for us in higher ed to assert that there are real opportunities moving forward for people pursuing those careers. The two elements of it are investments in supporting companies to build fabs here. The other important part is there a significant amount of funding in that Act to support advanced research in higher education institutions.

“So, those two things together create this real moment for us to bring people into the field.

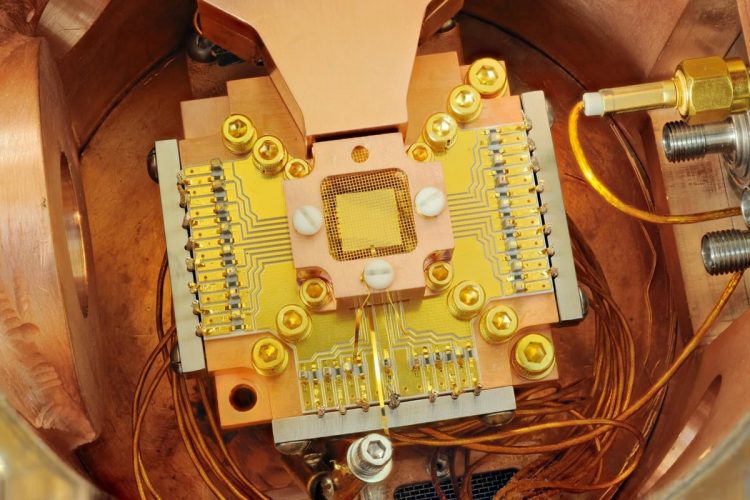

“While it’s important we’re reshoring these facilities and building these capabilities, what I think is really exciting is we’re at a point in time when people understand we’re at the end of Moore’s Law, which is the end of being able to scale devices in the classic sense. Now, we’re in an area of great invention of new types of architectures and new types of devices. Will it be a quantum computer? Will it be an optical?

“So, the space for innovation is really opening up in a way that creates real opportunities and excitement. You’re always going to be facing the fact that, particularly in the software space, the technology is not as capital intensive. So, their capacity to pay the salaries they do makes it an exciting market. But not everyone wants to code. So, I think what this does is create opportunities for those interested in hardware.”

How are you communicating that to students who see software development as more bleeding edge than hardware? “The short answer is: probably not enough. But, this advancement by the federal government gives us the opportunity to point to something tangible to excite students. The ideas for advancement have always been there. We can see the need for quantum computing, we can see the opportunities for planar optical devices. It’s one thing to see them, but when you don’t ultimately know when those things are going to be developed, that other part of the narrative makes it difficult to communicate. So, I think this investment is a huge lift for us as we talk to students about the opportunities.”

[Planar optical devices are one of the key technologies needed to create new generations of high-bandwidth communications systems.]

“Frankly, the other thing that’s really important in all this is in inventing the next-generation of technology, you have a much better chance of keeping it on shore if it’s invented in this country. Prior to the CHIPs Act, there was a great chance those inventions were going to be created elsewhere.”

You’re putting a lot of trust in the CHIPs Act. Is that really warranted? “Well, just in the build up to that legislation just getting signed, you saw commitments from Global Foundries, Intel, and Micron to make significant capital investments. And we’re also seeing that on a smaller scale, too. There’s a lot to be said for robust ecosystems. So, you don’t want to just have one player working in this area, which was the challenge for a company like Intel as fewer and fewer US-based companies where producing semiconductors on shore.

“So, I think in addition to big players making investments in fabs, we’re had conversations with much smaller companies that may be pursuing a niche area that uses the technology produced in these plants.

“My particular field of research throughout my career was in MEMS [Micro-Electro Mechanical Systems], which is basically making miniature sensors using the same [semiconductor] technology in terms of the processing capabilities. But when you don’t have the ecosystem around you — in terms of the equipment manufacturers and material suppliers and the big players who attract a lot of talent — some of [that] spills over to smaller companies. …That’s part of the story that’s not been contemplated. By investing in these large fabs, it’s attracting a lot more of the tail-end activity, which can lead to some of the most interesting inventions that end up driving the industry forward.”

Do you think the government is doing enough to push the industry forward? “In some respects, the CHIPs Act is having its intended impact in terms of unlocking capital investments to create fabs in the US, based on what we’ve seen thus far. I’d say the scale of the investment in R&D, particularly in universities, is very meaningful. It’s going to provide a lot of resources to universities that in some respects have struggled to attract those resources — particularly to have facilities to do some of the more advanced research that will lead to new production faculties. Are they enough? Time will tell.

“By the government making those investments, I think you’ll now see it unlocking some co-investments by the semiconductor sector, because now we’re in business and will have the capability to work directly in partnership with those industries.”

When you say co-investments, are you talking about businesses or other government agencies? “I think you’ll see some of the federal agencies funding some real leading-edge ideas in quantum computing and perhaps some other areas. But, I think because there’ll be more talent, faculty, and students working in these areas, companies will naturally come to universities for opportunities to work in partnership with the government or in ways that are complementary to the research activities that are being enabled by federal investments.”

What relationships does RPI have with semiconductor companies and startups today, and how are you looking to strengthen those connections? “RPI has had a history of a strong presence in the semi-conductor area. I’d say today it’s a little bit reduced compared to 20 years ago or so. But that’s in large part due to the decline in industrial activity. It’s something we intend to grow.

“In this particular region, we have a huge advantage in that we have the Albany Nanotech Complex, which is probably the only type of facility of its kind in the world where leading-edge semiconductor capabilities can be developed. And we have a tight relationship with them, as well as IBM in Albany, which is an active participant there. We also have in our backyard Global Foundries, which is, I think, the largest US-based foundry business.

“Then, most recently, we have Micron’s commitment to the upstate region. And we’re in conversations with all those entities as to how we can build partnerships.”

Probably the biggest hurdle right now to creating these chip fabs is finding the workers to get them online and producing. Does the CHIPs Act do enough? “Clearly, part of that allocation is intended to go toward workforce development. I think the largest demand will be for what I call associate/bachelor degree level people working in the production environment. Then, the next level up, where fewer numbers of people will needed, is the bachelor’s degree and the advanced graduate degrees. We’ve all been having conversations about how we do this together. Hudson Valley Community College already has a program working with Global Foundries to do workforce development.

“What’s attractive to employees is these are great jobs, and I’m sure they’ll be well-paying jobs. With the commitment of the US government to keep these jobs in country, people can feel better about their likelihood of being around for a while. So, I think we’re up to the task and as the capacity is built up over the years, we’ll have time to help build up what workforce.”

Are you planning to change your curriculum to address the future needs of the semiconductor industry? “I don’t know that the curriculum will change dramatically. I think we’ll need to be prepared to educate more people. But as these new technology vectors begin emerging in quantum or optical computing, we may find it necessary to add more advanced courses to train people. You have some of your advanced graduate students who are particularly designed to make good researchers. But as these technologies become deployed and become more mainstream, then that content migrates down into the undergrad level, when now you’re not just training people to do research in the industry but to work in the industry. So, I suspect what you’re more likely to see is not so much a change fundamentally in the curriculum but, as these technologies are deployed, you’ll see it percolate into the undergrad programs.

“It’s a classic situation…, you take any technology, at some point and time it begins as a research project within the university. As a faculty member performing that research, you’re hiring graduate students to do that research. So, you develop advanced graduate subjects that describe the field and what’s going on, which provides these graduate students with the tools they need to do the research. As that research translates into actually commercial activity, now what you were once teaching as a way to get people to do research, you’re now teaching it to bachelors-degree students who are going to work in the companies using the technology.

“It’s hard to overstate the importance of the research that will happen that will invent the future — and in doing that, it will hopefully stay here.”

Source by www.computerworld.com