EDA software is a small but mighty part of the semiconductor supply chain, and it’s mostly controlled by three Western companies. That gives the US a powerful point of leverage, similar to the way it wanted to restrict access to lithography machines—another crucial tool for chipmaking—last month. So how has the industry become so American-centric, and why can’t China just develop its own alternative software?

What is EDA?

Electronic design automation (also known as electronic computer-aided design, or ECAD) is the specialized software used in chipmaking. It’s like the CAD software that architects use, except it’s more sophisticated, since it deals with billions of minuscule transistors on an integrated circuit.

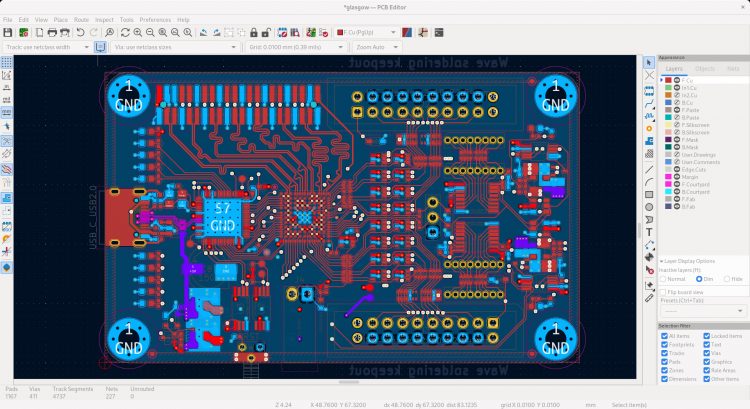

Screenshot of KiCad, a free EDA software.

JON NEAL/WIKIMEDIA COMMONS

There’s no single dominant software program that represents the best in the industry. Instead, a series of software modules are often used throughout the whole design flow: logic design, debugging, component placement, wire routing, optimization of time and power consumption, verification, and more. Because modern-day chips are so complex, each step requires a different software tool.

How important is EDA to chipmaking?

Although the global EDA market was valued at only around $10 billion in 2021, making it a small fraction of the $595 billion semiconductor market, it’s of unique importance to the entire supply chain.

The semiconductor ecosystem today can be seen as a triangle, says Mike Demler, a consultant who has been in the chip design and EDA industry for over 40 years. On one corner are the foundries, or chip manufacturers like TSMC; on another corner are intellectual-property companies like ARM, which make and sell reusable design units or layouts; and on the third corner are the EDA tools. All three together make sure the supply chain moves smoothly.

From the name, it may sound as if EDA tools are only important to chip design firms, but they are also used by chip manufacturers to verify that a design is feasible before production. There’s no way for a foundry to make a single chip as a prototype; it has to invest in months of time and production, and each time, hundreds of chips are fabricated on the same semiconductor base. It would be an enormous waste if they were found to have design flaws. Therefore, manufacturers rely on a special type of EDA tool to do their own validation.

What are the leading companies in the EDA industry?

There are only a few companies that sell software for each step of the chipmaking process, and they have dominated this market for decades. The top three companies—Cadence (American), Synopsys (American), and Mentor Graphics (American but acquired by the German company Siemens in 2017)—control about 70% of the global EDA market. Their dominance is so strong that many EDA startups specialize in one niche use and then sell themselves to one of these three companies, further cementing the oligopoly.

What is the US government doing to restrict EDA exports to China?

US companies’ outsize influence on the EDA industry makes it easy for the US government to squeeze China’s access. In its latest announcement, it pledged to add certain EDA tools to its list of technologies banned from export. The US will coordinate with 41 other countries, including Germany, to implement these restrictions.

Source by www.technologyreview.com